About Additive Manufacturing in Medical

Additive manufacturing is reshaping the medical industry by providing faster, more customizable, and cost-effective solutions for medical devices, surgical instruments, and patient-specific components.

Unlike traditional methods such as casting or machining, additive manufacturing allows for lighter, stronger, and highly tailored parts with no expensive tooling.

The process eliminates minimum order quantity constraints, making it ideal for custom implants, rapid prototyping, low-volume production, and clinical innovations where time and precision matter most.

From Prototype to Patient, Faster

Robust Technology Options

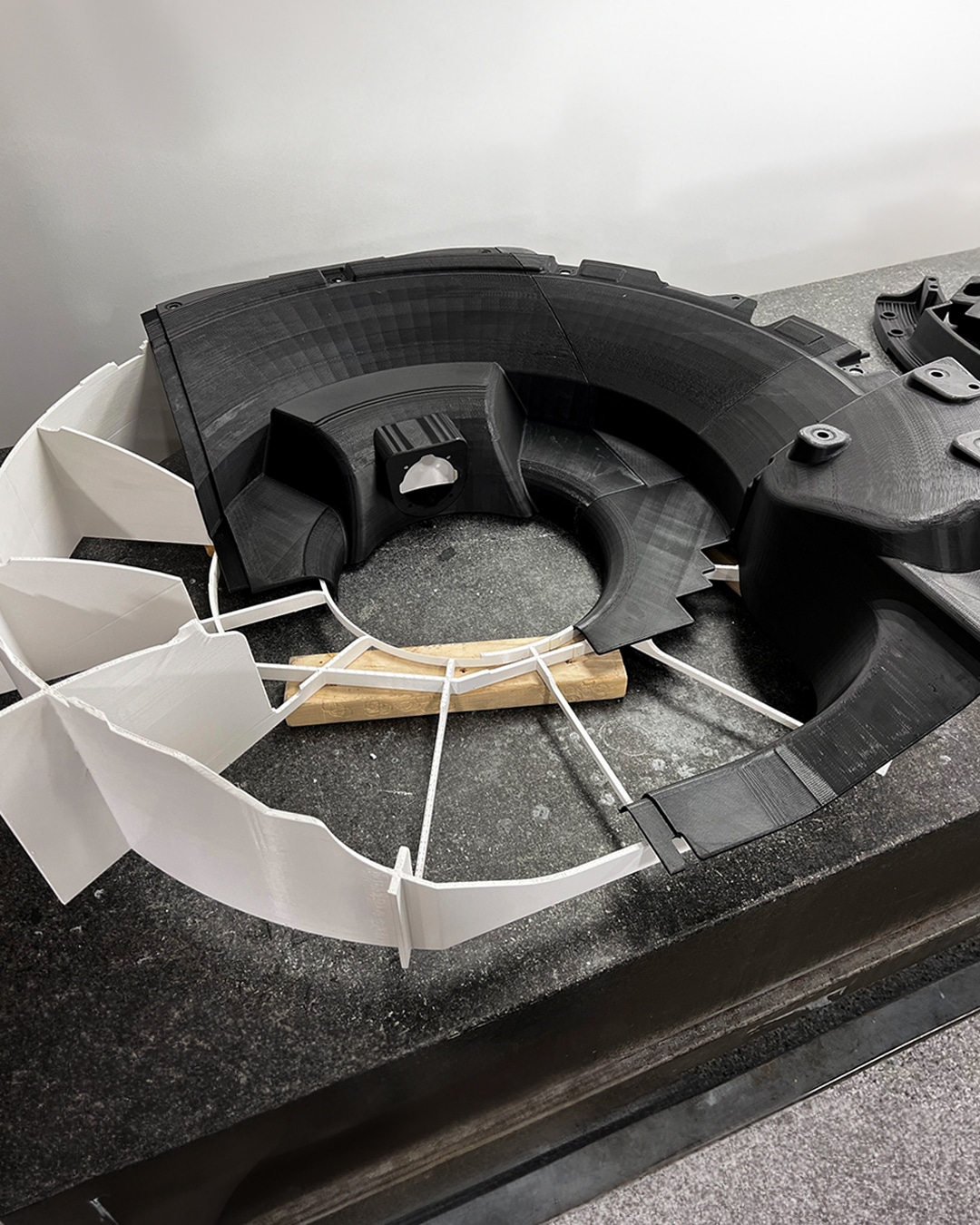

Evology’s additive toolkit includes DMLS for metal implants and struments, FDM for large prototypes and fixtures, SLA for high-resolution models,, and PolyJet for complex geometries. Combined with in-house finishing and validation, we deliver medical-grade results at manufacturing speed.

Leading Application Capabilities

- Custom surgical instruments

- Orthopedic implants & prosthetics

- Patient-specific anatomical models

- MRI & imaging system components

- Dental appliances

- Surgical cutting & drill guides

- Sterilization trays and fixtures

- Biocompatible housings and enclosures

Our Experience and Capacity

Expertise in Digital Sheet Metal Forming (DSMF) + Additive

Evology brings together metal additive manufacturing and tool-less sheet forming to create medical-grade prototypes and production-ready components. This hybrid capability accelerates design validation, reduces costs, and enables complex geometries that traditional manufacturing can’t match.

With ITAR registration and aerospace-level discipline, Evology delivers precision, compliance, and speed which are critical for the medical industry. Whether you’re iterating a surgical tool design or scaling a new device, we provide reliable, FDA-conscious manufacturing support from prototype through production.

Frequently Asked Questions

Transform Your Medical Projects with Additive Manufacturing

Looking for a partner who can deliver healthcare-ready parts with speed and precision? Evology’s additive manufacturing services empower innovation in medical devices, implants, and surgical solutions.

Contact us today to explore how additive manufacturing can accelerate your next medical breakthrough.