About Additive Manufacturing in Aviation

Additive manufacturing is transforming the aviation industry by enabling faster, more efficient, and highly precise production of aircraft components. Compared to traditional methods like casting, forging, or machining, additive manufacturing delivers lighter-weight parts for improved fuel efficiency, complex geometries for enhanced performance, and reduced lead times across design and production.

The technology also minimizes the need for costly tooling and eliminates traditional minimum order quantity (MOQ) restrictions, making it ideal for rapid prototyping, low-volume aerospace parts, custom solutions, and mission-critical performance innovations.

Bring Your Aviation Parts To Life

Leading Application Capabilities

- Lightweight Brackets & Mounts

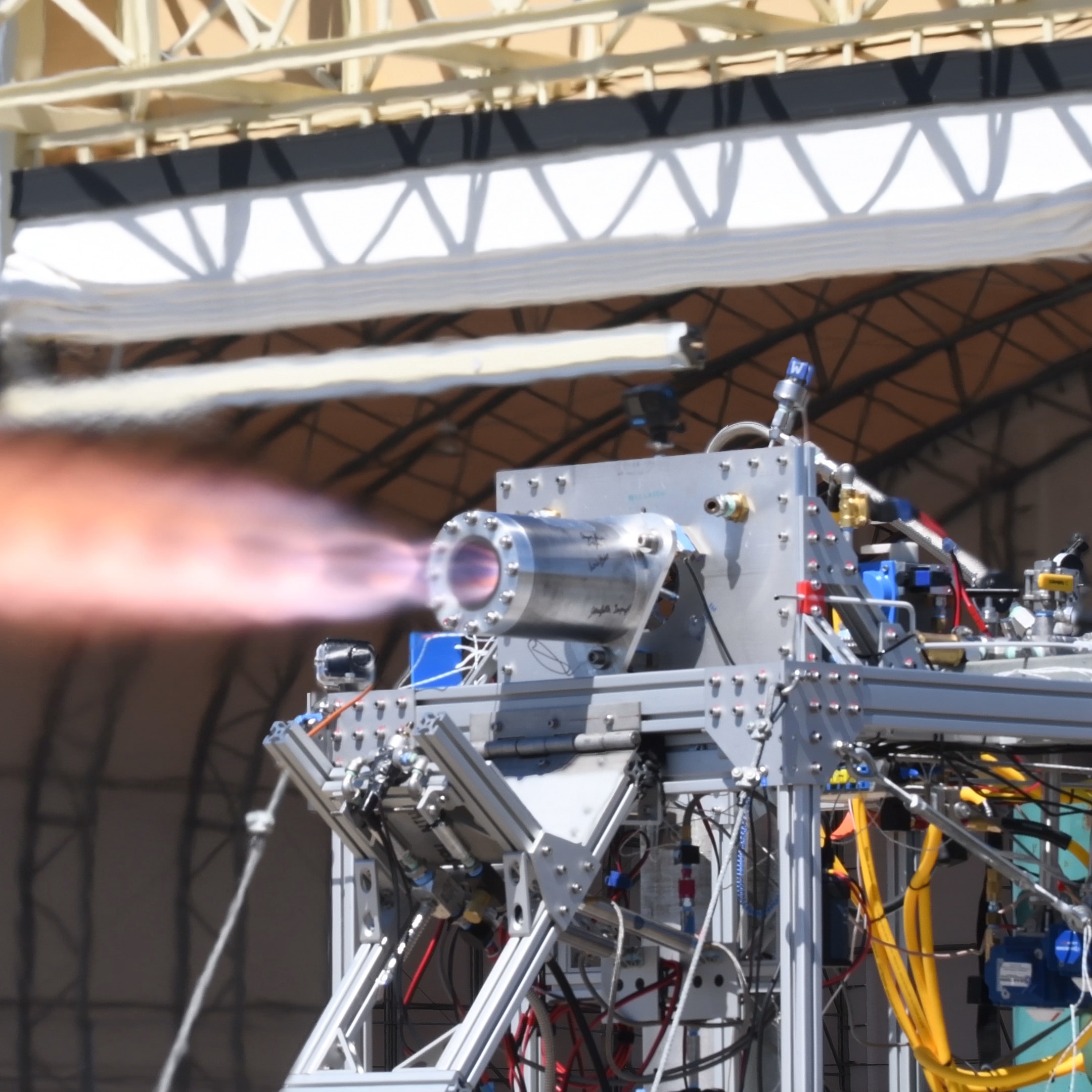

- Fuel Nozzles & Injectors

- Turbine Blades & Stator Vanes

- Interior Cabin Components

- Air Ducting & ECS

- Drone & UAV Structures

- Repair & Replacement Parts

- Composite Tooling & Jigs

- Heat Exchangers

- Prototyping & Wind Tunnel Models

- Landing Gear Components

Our Experience and Capactity

Expertise in Aviation Additive Manufacturing

Our direct experience with additive manufacturing in aviation has enabled us to deliver lightweight, high-strength components for both commercial and defense aircraft. From airframe brackets and structural supports to engine components and interior assemblies, we have successfully produced custom prototypes and final parts that meet the demanding standards of the aerospace industry. This work highlights the versatility and effectiveness of additive manufacturing in reducing lead times, improving fuel efficiency, and enabling complex geometries that traditional methods can’t achieve.

Whether it’s for rapid prototyping of aerospace components or low-volume production runs, our expertise in additive manufacturing allows us to provide aviation clients with cost-effective, FAA-minded, and ITAR-registered solutions. With Evology Manufacturing on your side, you can be confident in the precision, reliability, and airworthiness of every product we deliver.

Frequently Asked Questions

Transform Your Aviation Projects with Additive Manufacturing

Looking for a cutting-edge solution that delivers speed, precision, and design flexibility? Our additive manufacturing services are built to bring your concepts to life, faster and smarter than anyone else. Contact us today to explore how 3D printing and advanced manufacturing can accelerate your next project.