About Additive Manufacturing in Electronics

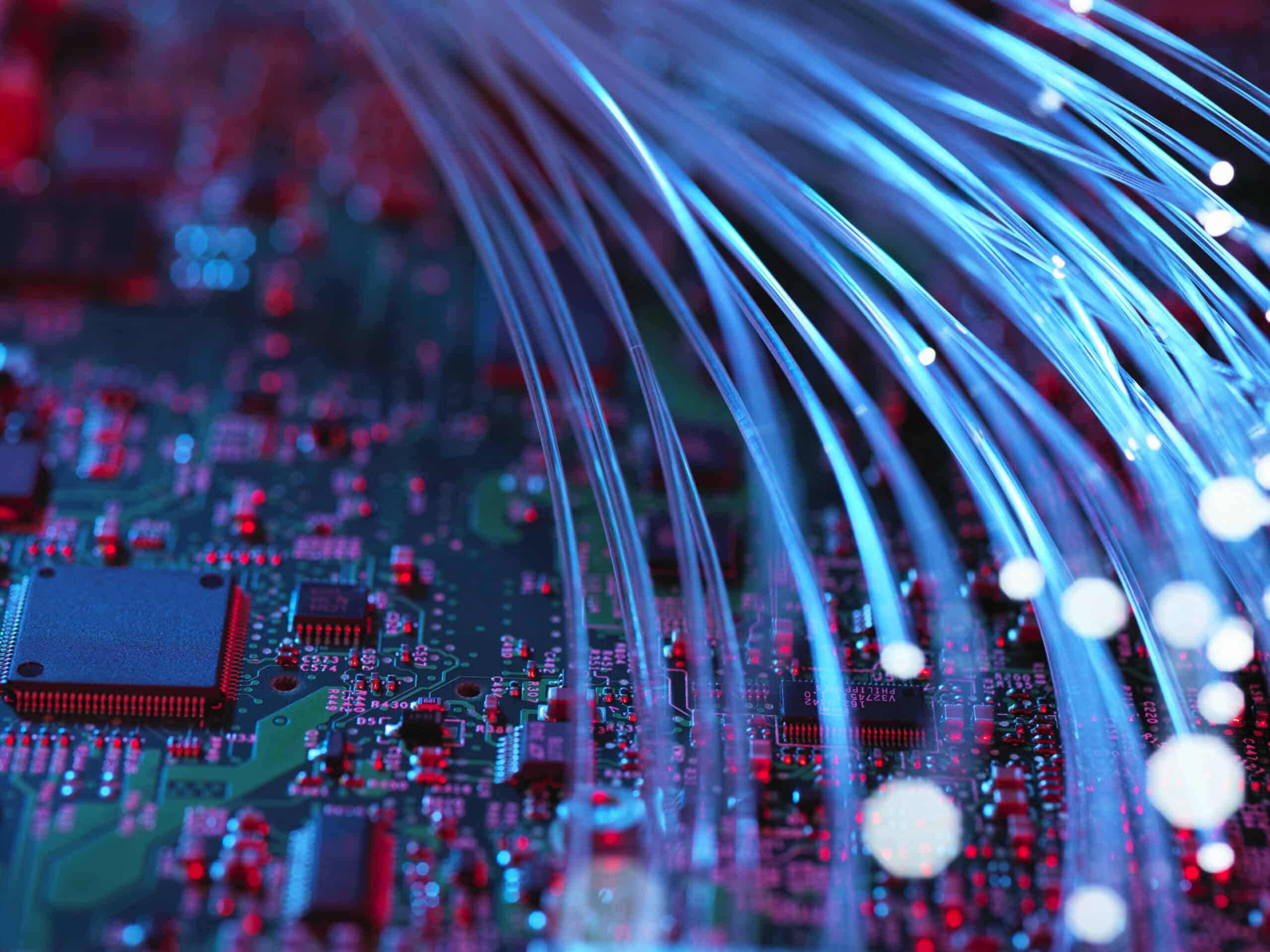

Additive manufacturing is transforming electronics by enabling faster development, greater design flexibility, and lower production costs.

Unlike traditional methods that require expensive molds or machining, additive manufacturing allows for lightweight, complex, and highly accurate components without tooling. By eliminating minimum order requirements, it’s the ideal solution for rapid prototyping, low-volume production, functional enclosures, and advanced electronic assemblies where time-to-market and precision matter.

From Concept to Circuit, Faster

Robust Technology Options

Evology’s capabilities span DMLS for metal components, FDM for durable fixtures and large prototypes, SLA for high-resolution details, and PolyJet for multi-material assemblies. With in-house finishing and redundant equipment, we deliver functional, production-ready electronic components with accuracy and speed.

Leading Application Capabilities

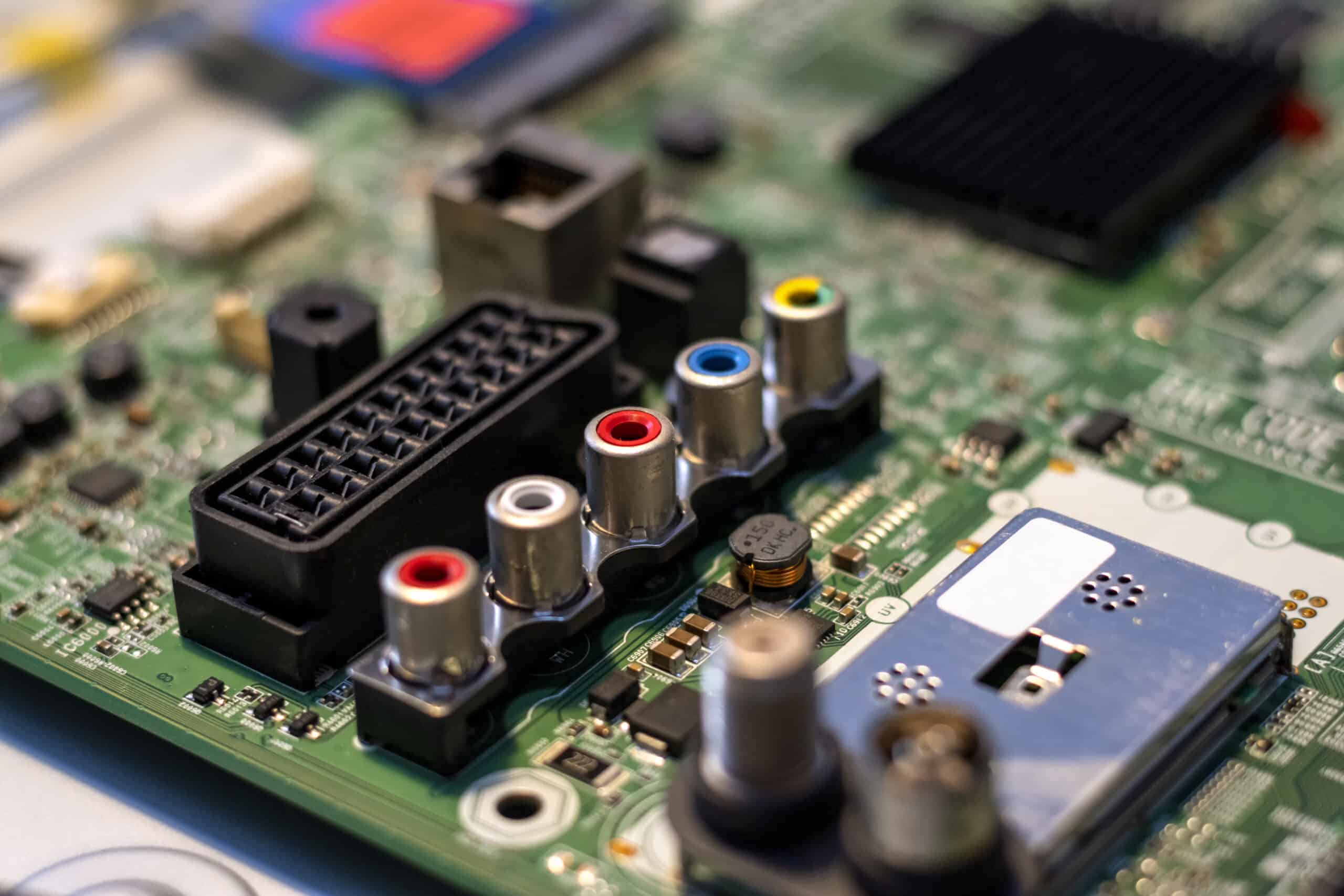

- PCB test fixtures and housings

- Enclosures for consumer and industrial electronics

- Thermal management components

- RF and EMI shielding prototypes

- Custom brackets and mounts

- Connector housings

- Lightweight structural supports

- Trade show and demo models

Our Experience and Capacity

Expertise in Additive + Digital Sheet Metal Forming (DSMF)

Evology integrates advanced additive processes with tool-less sheet metal forming to deliver components that support both prototyping and low-volume production. This hybrid approach reduces time, lowers cost, and provides flexible manufacturing for complex electronic assemblies.

With ITAR registration, aerospace-level quality standards, and in-house finishing, Evology ensures that electronic components meet the demands of industries where precision and reliability are critical.

Frequently Asked Questions

Transform Your Electronics Projects with Additive Manufacturing

Looking for a partner who can deliver high-precision parts on accelerated timelines? Evology’s additive manufacturing services help electronics innovators move from prototype to production faster than ever.

Contact us today to see how we can power your next electronics breakthrough.