About Additive Manufacturing in Automotive

Advanced 3D Printing and Rapid Prototyping Technologies

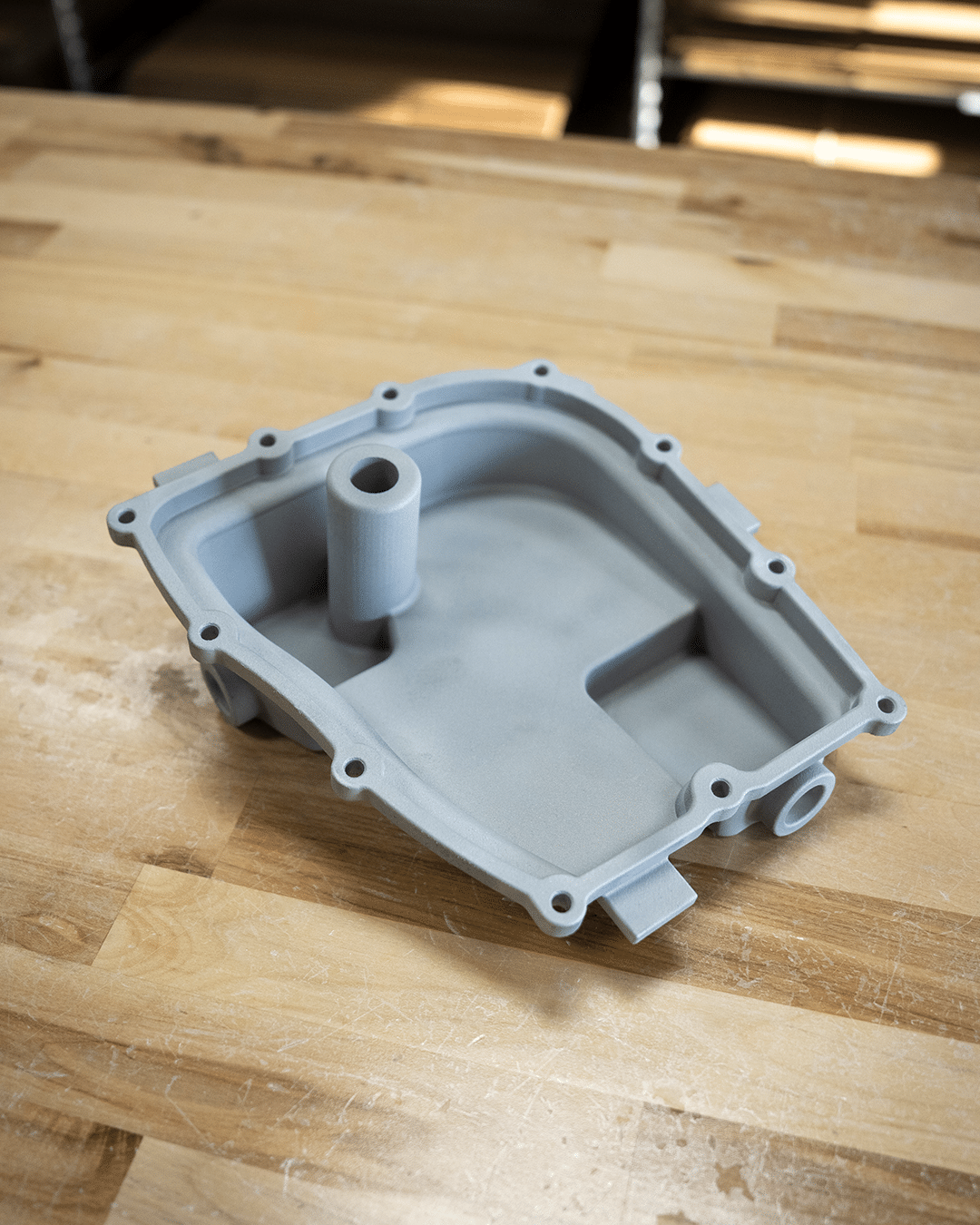

Additive manufacturing is reshaping the automotive industry, offering a faster, more flexible, and cost-effective approach to vehicle design and production. Compared to traditional manufacturing methods like casting, forging, or stamping, Additive Manufacturing provides advantages including shorter development cycles, reduced need for expensive tooling, lighter and stronger component options, and lower overall production costs. Additive manufacturing also eliminates traditional minimum order quantity (MOQ) constraints, making it ideal for rapid prototyping, low-volume production, custom parts, and performance innovations.

Bring Your Automotive Products To Life

Quotes in hours, Delivery in Days. Rapid Prototyping and Low Volume Production

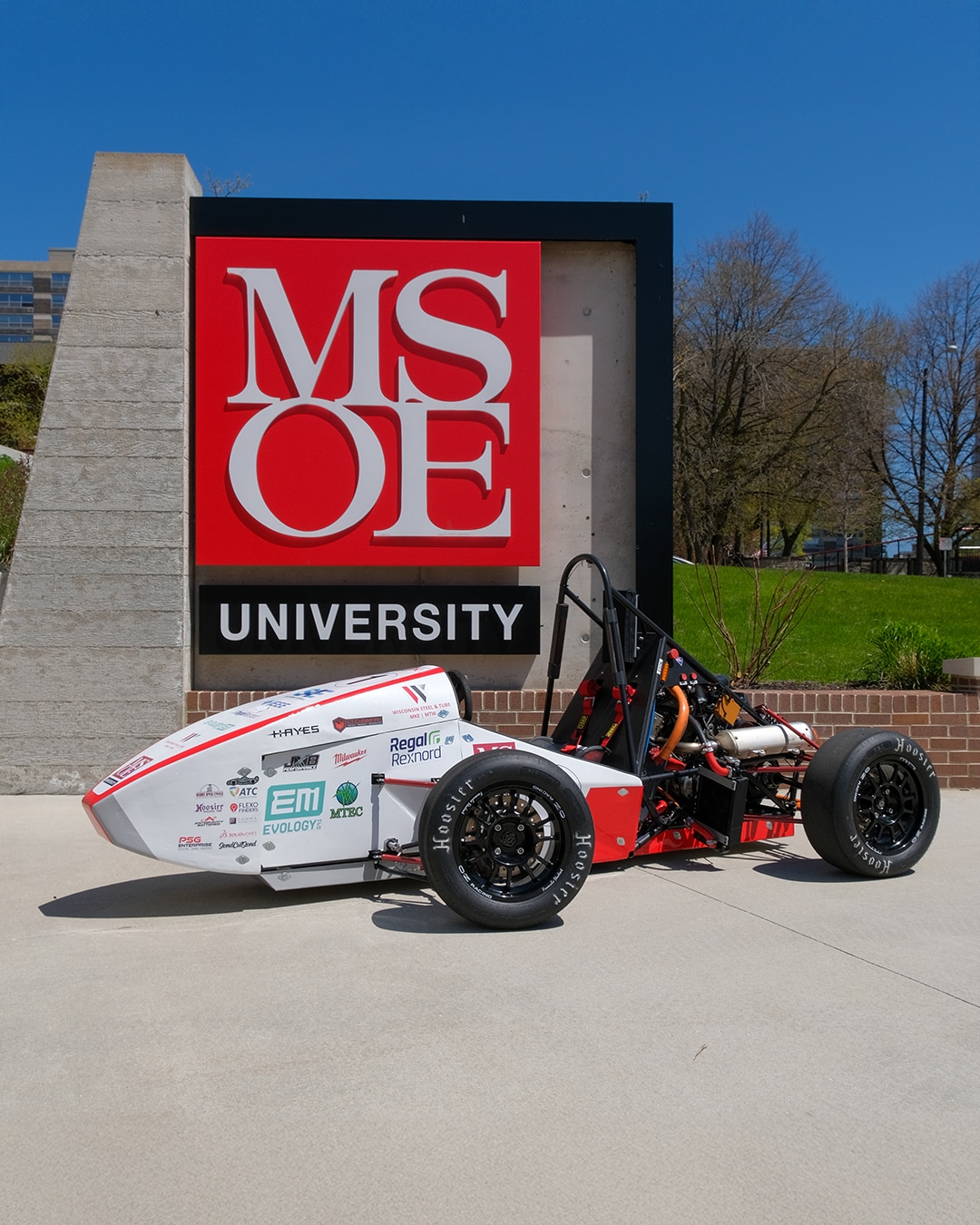

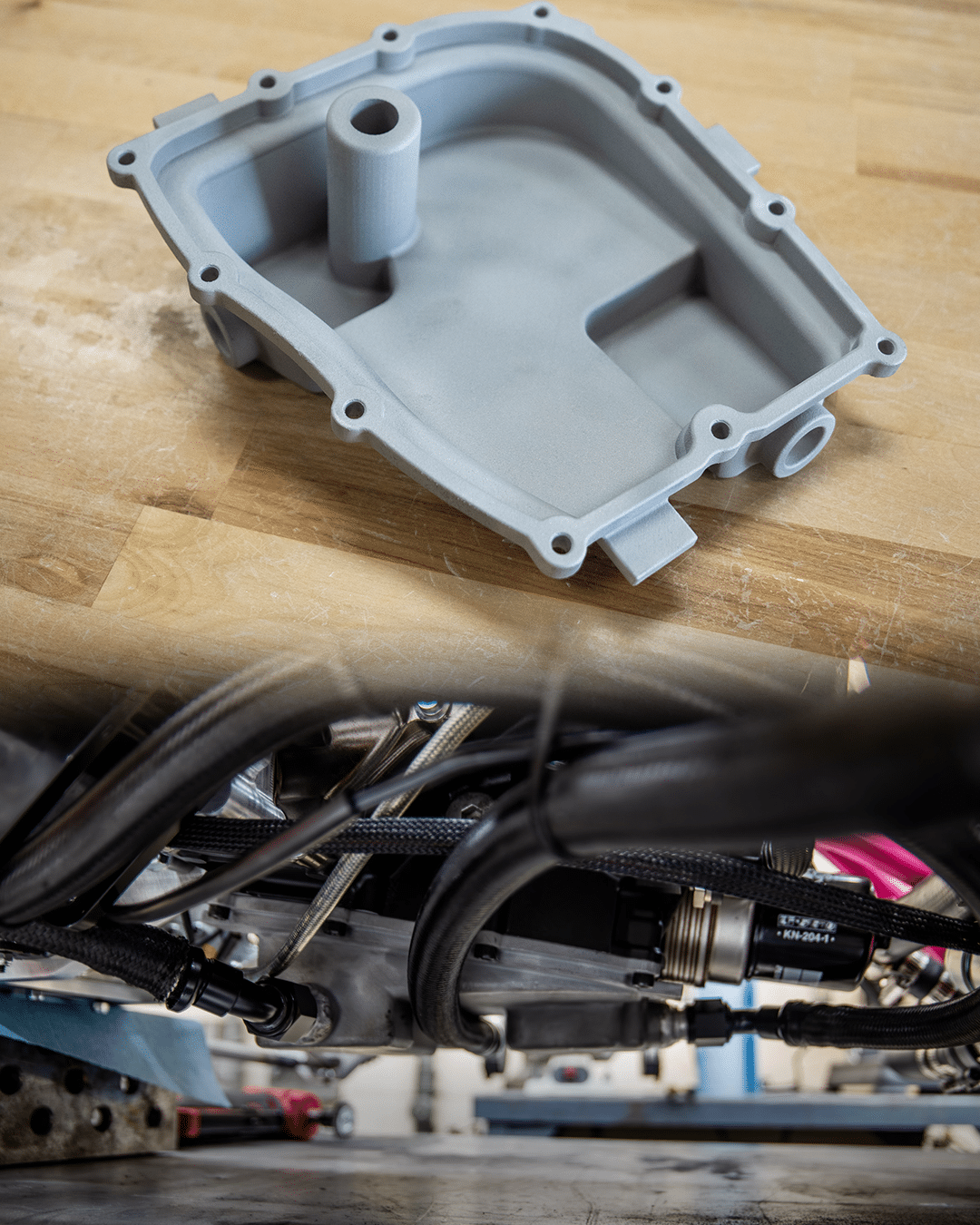

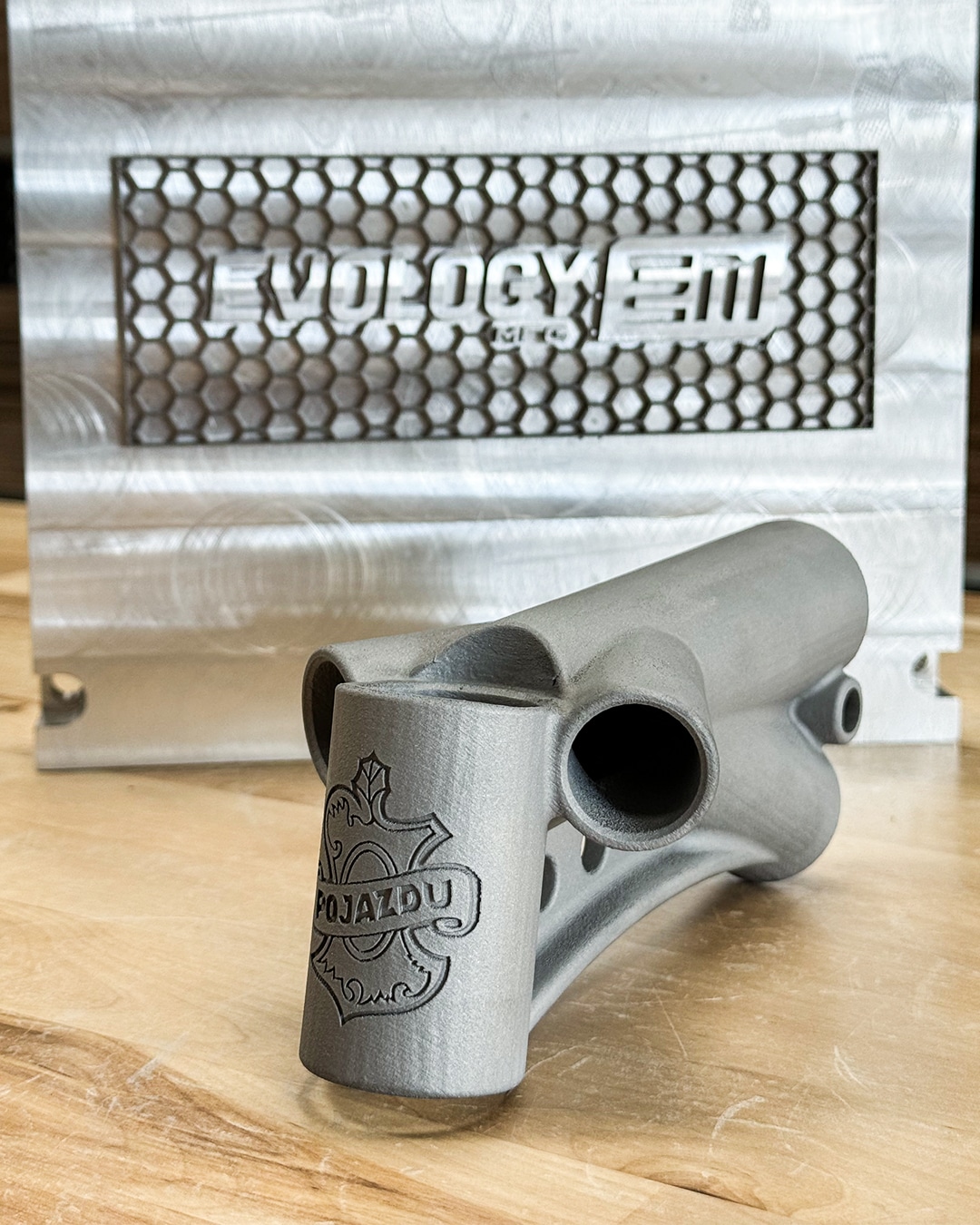

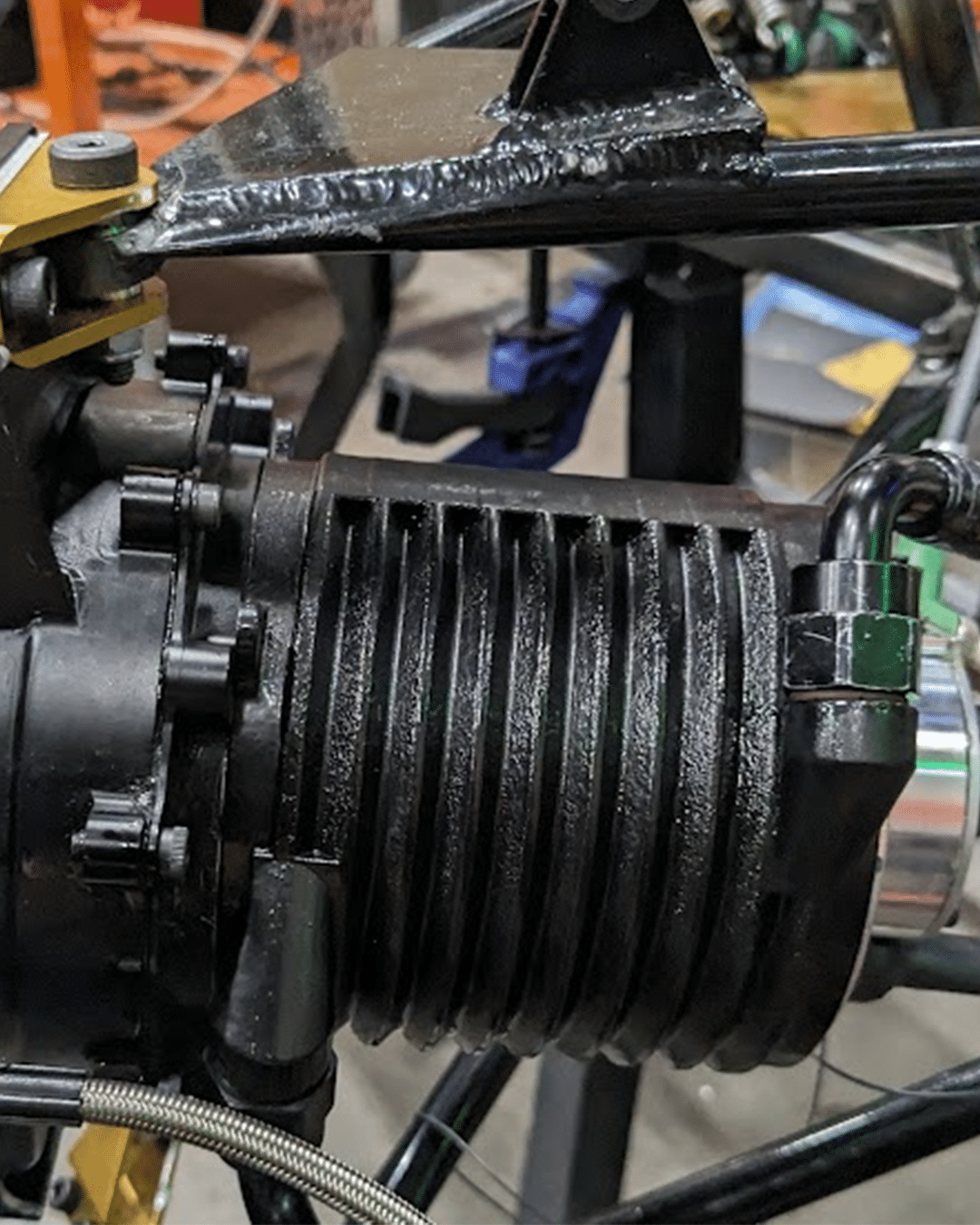

Case Study

Leading Application Capabilities

- Body Panels

- Engine Components

- Interior Trim

- Door Panels

- Display Bezels

- Trade Show Models

- Metal Structural Components

- Drill Fixtures

- Performance Cast Metal Components

- HVAC Ducts

Our Experience and Capactity

Expertise in Digital Sheet Metal Forming (DSMF)

Our direct experience with Digital Sheet Metal Forming has allowed us to cater to a wide range of industries, from aerospace and automotive to medical and consumer goods. We have successfully delivered custom prototypes and final products that have exceeded our clients’ expectations, showcasing the versatility and effectiveness of this manufacturing method.

Whether it’s for rapid prototyping or high-volume production, our expertise in Digital Sheet Metal Forming enables us to provide our clients with cost-effective and timely solutions for their additive manufacturing needs. With Evology Mfg. on your side, you can be confident in the quality and reliability of the products we deliver.

Frequently Asked Questions

Transform Your Automotive Projects with Additive Manufacturing

Looking for a cutting-edge solution that delivers speed, precision, and design flexibility? Our additive manufacturing services are built to bring your concepts to life — faster and smarter. Contact us today to explore how 3D printing and advanced manufacturing can accelerate your next automotive project.