Case Study:

Advancing Structural Innovation with Evology — Pioneer Racing FSAE’s PR25 DMLS Oil Pan

Partnering for Precision

For their 2024-2025 season, Pioneer Racing set out to strengthen the structural backbone of their Formula SAE vehicle, PR25. Building on lessons from the previous generation, the team reimagined the powertrain not just as an engine system but as an integral component of the chassis structure. Their goal demanded a part that was lightweight, structurally reliable, packaging efficient, and manufacturable under tight timelines.

This was not a job for traditional machining. This was a job for a partner who could keep pace with rapid iteration and complex engineering challenges, and that’s where Evology Manufacturing came in.

The Challenge:

PR25’s development was shaped by persistent issues carried over from earlier designs. The team wanted to reduce unnecessary mass, improve maintainability, and increase structural rigidity. The oil pan needed to do more than manage lubrication. It had to behave as a structural member tying the chassis to the rear plates while also enabling a dry sump system.

The design required:

• Integrated internal oil passages

• Minimal parallel faces

• Precise geometry validation

• Strict weight targets

• Weldable material for external fittings

Traditional machining could not meet these competing demands, however a DMLS printed solution could. Evology’s expertise in aluminum alloy DMLS, paired with fast iteration cycles, made them the ideal partner to solve this complex problem.

Design Iteration 1: Validating Structure Through Rapid Prototyping

From the outset, the Pioneer Racing team adopted a design for rapid prototyping mindset. The workflow began with CMM measurements and 3D scanning of the engine and mounting surfaces, followed by PLA prints to validate CAD accuracy against real engine geometry.

Once the baseline geometry was verified, the team advanced into functional design. Using SiAl10Mg, validated through tensile fatigue testing and proven effective on PR24, they produced their first DMLS ready iteration.

Key integrations included

• internal features to support engine loads

• externally welded threaded bungs for the oiling system

• early topology shaping guided by FEA feedback

This initial design already shed approximately one pound compared to the earliest concept, but this was just the beginning.

Design Iteration 2: Optimization Through Simulation

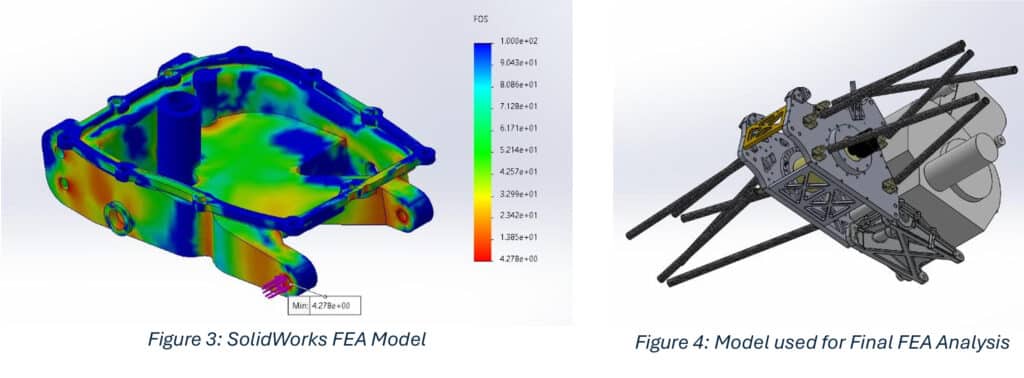

As complexity increased, simulation guided the refinement process. Pioneer Racing applied iterative FEA in SolidWorks to understand stress distribution quickly, while Ansys provided the final high fidelity static and fatigue simulations. These evaluated the oil pan as part of a full assembly including the engine, rear plates, and suspension.

Refinements between iterations included

• Tuned wall thickness to balance stiffness and mass

• Enhanced topology driven ribbing

• Improved internal oil flow passages

e• Extended precision surfaces for post machining

The final design weighed 3.4 pounds. Although slightly heavier than the previous year’s non structural pan, it now served both as a load bearing component and as the core of a dry sump system.

Manufacturing with Evology: Speed Meets Complexity

Once finalized, the design moved to Evology for production. Our DMLS workflow delivered the precision needed for the part’s internal channels and structural geometry, ant the alloy’s machinability ensured that critical mating surfaces could be refined with ease.

The complete manufacturing process, including printing, machining, and welded AN fittings, was completed in just two weeks. Even with minor fabrication challenges identified post print, the rapid turnaround reinforced DMLS as the right and perhaps only feasible approach for PR25’s structural oil pan.

Measured Results

On the track and in the workshop, the new oil pan delivered significant improvements.

• Increased structural stiffness improved integration of the powertrain with the rear assembly

• Enhanced dry sump oil management improved reliability under dynamic load

• Strategic weight placement produced system level performance gains

• Improved manufacturability and maintainability addressed major shortcomings from earlier designs

• Judges and fellow teams praised the engineering depth at competition

By combining advanced simulation, rapid prototyping, and Evology’s DMLS expertise, Pioneer Racing produced a component impossible to manufacture using conventional methods.

Moving Forward

With PR25, Pioneer Racing found a new competitive edge by embracing complexity and choosing the right manufacturing partner. Their collaboration with Evology did more than create a stronger, more capable oil pan. It expanded the team’s engineering capabilities in material testing, FEA, rapid prototyping, and additive manufacturing.

As the team looks toward future seasons, the foundation is set for even more ambitious structural integration and advanced additive techniques.

Evology Manufacturing is proud to support student engineers pushing the limits of design, performance, and modern manufacturing.