Digital Manufacturing Engineering & Case Studies

At Evology, we specialize in transforming your innovative ideas into high-quality products through additive and traditional manufacturing. Our portfolio showcases a range of projects that have undergone our engineered reviewed approval process, complete with essential project summaries, time-to-quote, and shipping schedules. Leveraging the latest in additive manufacturing, we offer rapid tooling and metal 3D printing services that cater to your specific industrial needs. Take the first step towards materializing your vision by using our simple request-a-quote feature, and let us handle the rest.

Case Studies

3D Printed Suspension Components

SEA Formula Car

We recently had the pleasure of working with the Georgia Tech Racing team to manufacture some 3D printed suspension components for their SAE Formula car. These parts were printed from Aluminum and we were able to get them in their hands with a fast turnaround time thanks to our incredible team. We wish the Georgia Tech Racing team success with any upcoming events and can’t wait for any future projects with them.

Technologies Used: DMLS

3D Rapid Prototype Components

UW Madison Baja Team

Working with the UW Madison Baja Team, we developed an upright components for their Baja car project and were able to deliver 2 different versions in less than 24 hours. While the plastic prints will be used as a mock-up, our future plans include a full additive manufacturing print in the future for the team to use!

Technologies Used: FDM

MRI Cover

Leveraging our largest FDM printing machines we were able to manufacture this MRI cover. Even though our machines are capable of printing large components, this part still required us to print it in multiple pieces. To ensure the assembly of the pieces was accurate we engineered and produced a custom assembly jig to streamline the final assembly process. This jig was also printed using the same Fortus 900MC FDM printer. This project underscores our commitment to pushing boundaries of additive manufacturing to deliver tailored solutions for complex challenges in the healthcare field.

Technologies Used: FDM

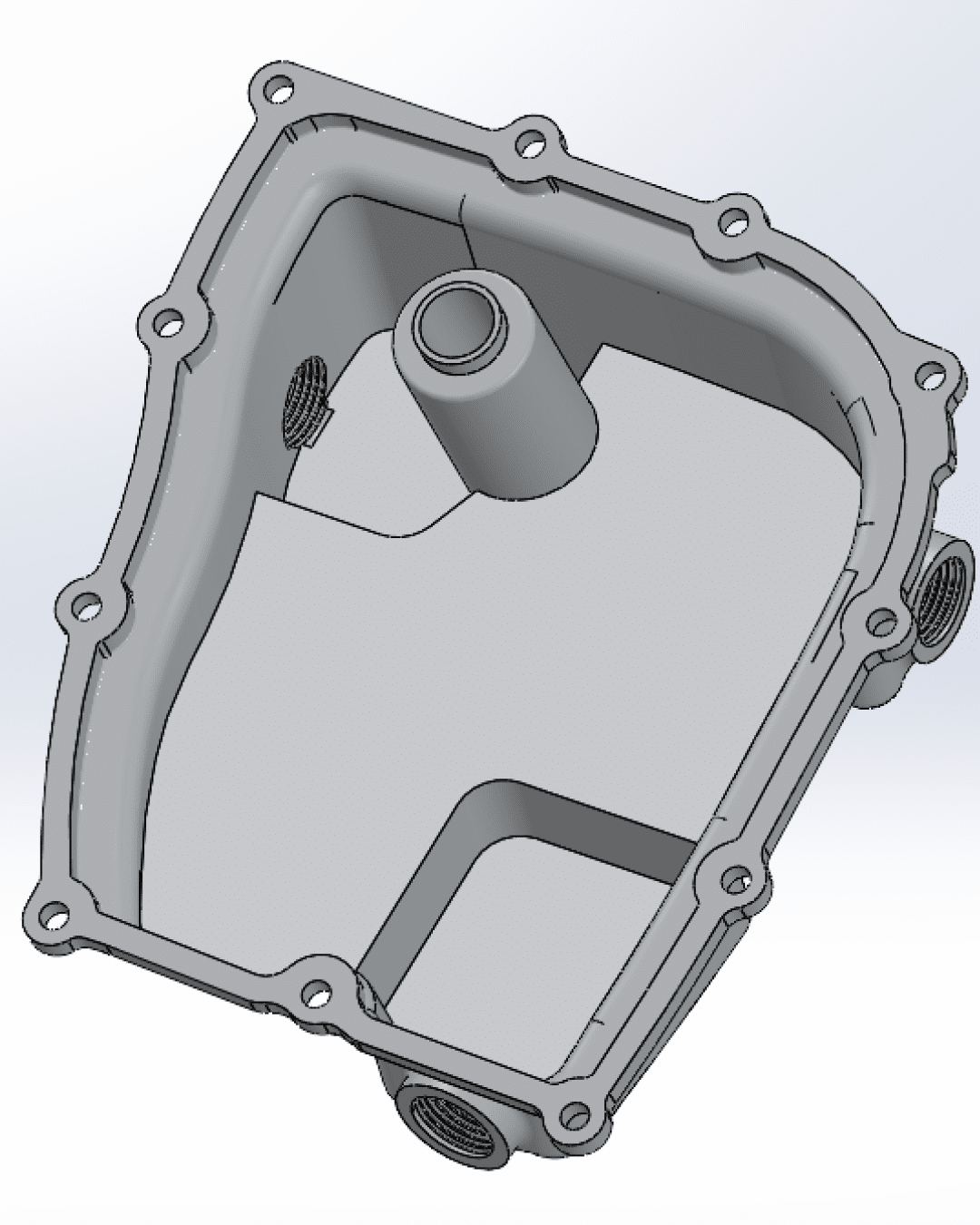

Custom Oil Pan

When the UW-Platteville SAE Formula team kept running into reliability issues with their Yamaha WR450 engine, they made the decision to move to a 700cc two-cylinder Yamaha CP2 engine. With a larger engine it was necessary to swap the original wet sump oil system to a dry sump system to allow for clearance between the engine and the ground when installed in the desirable location of the car’s chassis. To achieve this, the team needed to develop a custom oil pan for the engine. After spending a good amount of time working on a cast version of this custom oil pan that wasn’t guaranteed to work, the team decided that using additive manufacturing would be a better alternative. Evology was able to work with the UW-Platteville team to make this idea a reality, taking this custom idea from concept to reality. This custom 3D printed dry sump oil pan will allow for the necessary ground clearance with the larger engine on the car, ultimately ensuring the car performs when they need it most.

Technologies Used: DMLS